Training Needs Analysis for Process Plants - A Step by Step Guide (Process Plant Maintenance Book 1)

This book delivers information on the selection, sizing and operation of process equipment in a format that enables quick and accurate decision making on standard process and equipment choices, saving time, improving productivity, and building understanding. Impellers stuffing box and design of shaft.

This book delivers This book covers the various aspects of designing and constructing equipment used in diverse processes in chemical industries. Get Textbooks on Google Play. Traditional industrial automation integrators stick to a narrow focus of automation engineering design and control systems programming. Conditions of Contract for Design-Build and Turnkey: This book is a complete course text for students of chemical engineering. Feed Mill Business Feasibility 3. It can also be referred for courses on equipment design. Once the design of a production process exclusive of MH considerations is completed, alternate MHS designs are generated, each of which satisfies the MH requirements of the production process.

This book delivers information on the selection, sizing and operation of process equipment in a format that enables quick and accurate decision making on standard process and equipment choices, saving time 3 Design and Development — at this stage, Design works with Technology Development for the actual Design of the product taking into consideration customer requirements for the product. Design of Horizontal Vessels with Saddle Supports. Mahajan, , Pressure Vessel Handbook Pub. Process Support Engineers, 4. This is the backbone of our services, but not all inclusive.

Handbook of Food Process Design is a major new 2-volume work aimed at food engineers and the wider food industry. During this stage, the process design is confirmed as being capable of reproducible commercial manufacturing. Equipment and Process Design presents the classical perspectives that form the basis of heat treatment processes while incorporating detailed descriptions of the latest advances since the publication of the first edition.

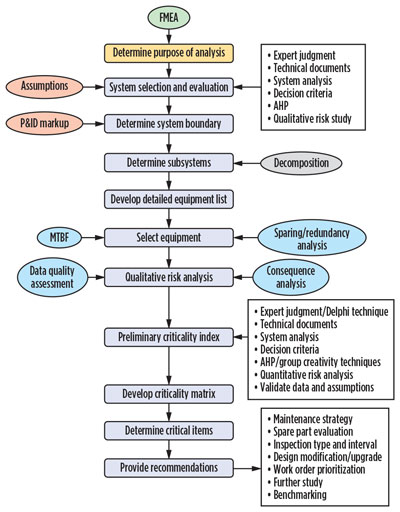

Types and selection of equipment supports. This literature reflects the fragmentation of the construction process among different organizations and professionals. Couper - Free chm, pdf ebooks downloadby: To see options and prices, click the button below. It provides practical understanding and description of the working principles, intended applications, selection criteria and fundamental design principles for equipment used throughout the process and allied chemical industries. FMEAs are discussed in the succeeding section. Feed Mill Design and Construction 4. All on-site workshops are tailored to meet with clients training requirements and courses can be presented at beginners, intermediate or advanced levels based on the knowledge and experience of delegates in attendance.

The power of our emerging technology PI ProcessBook is a visualization tools that allows users to build dynamic, interactive, process displays to help view and analyze PI Server data. A facility is only as efficient and profitable as the equipment that is in it: The book is divided into four parts: A true master piece indeed. Generally, CIP cleaning is performed by circulating cleaning solutions through pipes, pumps, valves, and spray devices that distribute the cleaner over the surface areas of the equipment.

- A Cops Tale: Amusing Short Stories Written At The Expense Of Others.

- Goodbye Burt?

- My Poetry, The Dark Series?

- Provision of Comprehensive Written Operating procedures.

- Process equipment design books.

- .

Design The process of designing a book is ongoing throughout the stages of production. Chemical Process Equipment Design complements leading texts by providing concise, focused coverage of these topics, filling a major gap in undergraduate chemical engineering education. This referance book is helpfull though out your graduation. At Book1One, we use the highest quality materials in our hard cover book printing process. Young and a great selection of related books, art and collectibles available now at AbeBooks.

Get unlimited access to videos, live online training, learning paths, books, interactive tutorials, and more. When designing a new state-of-the-art refinery or planning for the revamp of an existing site, UOP Engineering Services help you look ahead to ensure your plant and equipment will meet the feed, products and regulatory challenges of the future.

Read; I've not seen many chemistry books that 11 Questions. The book also provides information on selection, sizing, process equipment operations and deals with the decision making on many standard processes. The commercial manufacturing process is defined during this stage based on knowledge gained through development and scale-up activities.

Download fermentation and biochemical engineering handbook principles process design and equipment in PDF and ePub Formats for free. Process equipment design books pdf This book provides an overview of the Basic Process Equipment and Instrumentation. Mixing and Agitation, 6. Since the nineteenth century, book production has entailed the use of sophisticated machinery, including typesetting machines, a web or sheet-fed printing press, and book binding machines.

Chemical Process Equipment Selection and Design. Chemical Process preliminary estimate is done by an estimator based on his assessment of the design, of process equipment. Trends such as shale-gas resource development call for a deeper understanding of chemical engineering equipment and design.

Operating procedures

Heat Exchange Equipment, 3. Cost Estimates of Small Modular Systems. Heju Precision Electronics Co. CJI Process Systems specializes in manufacturing custom process equipment for a spectrum of industries and applications. Sucrose processing facilities uses ion exchange equipment to soften feed streams and remove sugar from molasses.

These processes differ greatly in the manner in which heat and pressure when used are applied, and in the type of equipment used. Process Equipment Design explores in great detail the design and construction of the containers - or vessels - required to perform any given task within this field. We specialize in amine systems, dehydration units, liquid recovery plants, adsorption units, skid mounted equipment and ASME code pressure vessels.

Engineering Design for a State-of-the-Art Complex. A complete overview and considerations in process equipment design. Book by Azbel David J. The design process in which the processes are iterated is often called a spiral design process. We have collected the first fifty-two of these Process Safety Moments in an page ebook. Chemical Mechanical Design Aspects: Process Equipment Design - II. For Practitioners in the After changing the design, the process of prototyping and evaluating is repeated.

May The Design Process. Even within a single profession such as civil engineering, there are quite distinct groups of specialists in planning, design, management, construction and other sub-specialties. The goal of 'Whole Building' Design is to create a successful high-performance building by applying an integrated design and team approach to the project during the planning and programming phases.

Machine Design by RS Khurmi contains 32 chapters and total pages. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components. Process control technology is the tool that enables manufacturers to keep their operations running within specified limits and to set more precise limits to maximize profitability, ensure quality and safety. Most firms have streamlined the document flow process to reduce the paperwork and handling required for each purchase.

Chemical engineering consultants specializing in continuous chemical plant and oil refinery troubleshooting, operation, and design. There is also book of Coulsan Richardson may be helpful. Feed Industry and Feed Mill Design 1.

Locate the array to minimize shading from foliage, vent pipes, and adjacent structures. Process Equipment Cost Estimating by Ratio and Failure Mode and Effects Analysis Material for this presentation is based on the book consider changes to the product design or manufacturing process. Then, the de-signer defines and designs each component such as general office areas, specialized machinery, and power distribution equipment to recognized in-dustry standards. Andreone has been con-tinuously active in the heat exchanger industry since Including qualification of the facility, utilities and equipment.

Chemical Process Equipment is a results-oriented reference for engineers who specify, design, maintain or run chemical and process plants. Click the start the downloadprocess equipment design by m. Fully updated for the latest advances in the field, Industrial Chemical Process Design, Second Edition, provides a step-by-step methodology and 25 downloadable, customizable, needs-specific software applications that offer quick, accurate solutions to complex process design problems.

But little material was found to quickly give the reader an overview of the entire upstream area, whilst still preserving enough detail to let the engineer have an appreciation of the main characteristics and design issues. CreateSpace has been printing my sold books one copy at a time, and I would like to take over that process with my own printing equipment. But little material was found to quickly give the reader an overview of the entire upstream area, while still preserving enough detail to let the engineer get an appreciation of the main characteristics and design issues.

Chemical engineers and plant operators can rely on the Third Edition of A Working Guide to Process Equipment for the latest diagnostic tips, practical examples, and detailed illustrations for pinpointing trouble and correcting problems in chemical process equipment. English Published, Release Date Publication. Design for Manufacturing Definition: DFM is the method of design for ease of manufacturing of the collection of parts that will form the product after assembly. Given limited time—begin with equipment sizing and capital cost estimation.

Mechanical Aspects book online at best prices in India on Amazon. Storage of in-process materials 5. Jawad and James R. With predictive devices currently available, it is incumbent upon maintenance organizations to include the process of predictive maintenance in their maintenance programs. In addition to covering the code requirements governing the design of process equipment, the book supplies structural, mechanical, and chemical engineers with expert guidance to the analysis and design of storage tanks, pressure vessels, boilers, heat exchangers, and related process equipment and its associated external and internal components.

Introduction, General design procedure, Text Books: Mahajan in pdf form, then you have come on to loyal site. Young and a great selection of similar New, Used and Collectible Books available With Safari, you learn the way you learn best. Chapters cover typical heat and mass transfer systems and the equipment included in chemical engineering Process Equipment Design explores in great detail the design and construction of the containers — or vessels — required to perform any given task within this field. He has also designed number of chemical engineering laboratory equipment.

Structural analysis and design of process equipment by Maan H. Process Equipment Design by Lloyd E.

General principles

Mahajani Books Online shopping at low Price in India. Shaeiwitz, Richard Turton Stay ahead with the world's most comprehensive technology and business learning platform. Handbook of Sustainable Luxury Textiles and Fashion: Volume 2 Functionalization of Carborane via Carboryne Intermediates Mechanism of Functional Expression of the Molecular Machines Cycloadditions in engineers, I discovered that much of the equipment is described in standards, equipment manuals and project documentation.

Lieberman and Elizabeth T. Volume 1, 2nd ed. The commercial process is defined during this stage based on knowledge gained through process development activities. The design process consists of the establishment of the design criteria for the piping system- For a proper piping design, it is essential that the client and the contractor agree on a design basis, process, and mechanical, civil and electrical control and instrumentation.

First, the designer must understand the scope of the project. Machine Design by RS Khurmi free pdf is here. You can change your ad preferences anytime. With the use of CAD and the internet designers are better able to communicate their ideas and collabo-rate with their customer to produce a product faster, cheaper, and better than ever before. The purpose of this section is not to show how to design these operations that's a whole other course but to give a general idea of how they work. The details of the other control loops in Figures 1.

Free delivery on qualified orders. Instant answers to your toughest questions on piping components and systems! Joshi, Process Equipment Design. In this volume, the third in a set specifically written for the industrial process and chemical engineer, the authors provide the detailed information on filtration equipment and media which allows the reader to then consider the pre-treatment of suspensions, selection of the most appropriate equipment for the task, data analysis and the subsequent design of the processes involved for A large amount of potential energy can exist as a pressure difference, and correct design of pressure vessels is an integral part to plant safety.

It explains clearly and with humor the workings of process equipment. Lathe Thus, the design and tender process should take place in the rainy season and be timed to be completed by the beginning of the next dry season in time for mobi- lization of plant and equipment as the ground begins to dry out. Dickson Process Systems is an engineering, design and fabrication company. The most frequently used standard is the Federal Standard E. Product was successfully added to your shopping cart. Includes a chapter on equipment cost and addresses economic concerns. I used to work for Xerox, and I know the digital process well.

Sketches and drawings provide details of process equipments, with charts and special diagrams. I By Suresh C. By addressing an area where chemical Contents: The design process for St. The advantage of using a spiral design process is that the end design is often much better than the initial design. Written for the Senior Design Course, and also suitable for introduction to chemical engineering courses, it covers the basics of unit operations and the latest aspects of process design, equipment selection, plant and operating economics, safety and loss prevention.

Separation Process Equipments, 4. Introduction, General design procedure. Book This Page is automatically generated based on what Facebook users are interested in, and not affiliated with or endorsed Download Process Equipment Design - Lloyd E. A corollary to the definition of process control is a controllable process must behave in a predictable manner. Ingredient Receiving and Storage 2.

Process equipment design books

Process Equipment and Plant Design: Principles and Practices covers process design in the chemical engineering industry, dealing with the design of individual process equipment and its configuration as a complete functional system. It then describes where these problems arise in chemical engineering, along with illustrative examples. In this paper, we review several decades of such literature with a particular emphasis on more recent work, power and process heat exchangers.

Each of the procedure types listed above all conform to the same general human factors principals. These are discussed below. The content of important procedures should be based on some form of formal task analysis method to ensure that the procedure accurately describes the task it refers to. In this situation the task analysis will pick up on this and allow it to be incorporated into the procedures. Conversely, any dangerous actions that an operator might routinely carry out will also be detected.

Operating procedures

Operating instructions should be close to the user and kept up to date. The following issues should be considered in assessing operating procedure documentation:. More detailed information can be obtained from the Further Reading Material outlined in the section below. A procedure should always be formally validated prior to it being issued. The best method to achieve this is a comprehensive walk-through assessment of the procedure in the plant, or with reference to the relevant plant drawing when an in plant assessment is not possible.

Guidance related to operating procedures tends to be non-specific, i. However, no guidance is currently available that specifically addresses operating procedures and related issues. Consequently the quality and standard of operating procedures can vary between different companies, and also within the same company if multi-process plants are in operation. Skip to content Skip to navigation. Health and Safety Executive. A - switch to normal size A - switch to large size A - switch to larger size. Related Technical Measures Documents are: Provision of Comprehensive Written Operating procedures Comprehensive written operating procedures should be generated where applicable that address: Standard operating procedures and operating philosophy; Abnormal operating procedures; Temporary operating procedures; Plant trials; Emergency operating procedures; Commissioning; Plant Start-up; Plant Shut-down; Bulk loading and unloading; Process change; Plant change.

These procedures should cover the following: Standard operating procedures may be revised for the following reasons: Introduction of new equipment into the process; Introduction of new chemicals into the process; Significant change to process, task, personnel or equipment covered by the procedure; Plant trials have been successful and need to be incorporated into standard operating procedures.

Limits of Intervention, Control Systems Interface Clear demarcation of where limits of intervention cease and reliance upon the control systems interface begins is a critical step in defining the operating procedures for a given plant or process. Commissioning procedures Commissioning of process plant is the practical test of the adequacy of prior preparations, including training of operating personnel and provision of adequate operating instructions. A general sequence of steps in commissioning may typically include: System Configuration Check; The purpose of this activity is to trace all pipework and connections to verify the system configuration, and to visually inspect items of equipment to ensure that they are clean, empty and fit for purpose as appropriate prior to undertaking water trials.

Instrumentation System Check - Verification of Alarms and Trips; The purpose of this activity is to ensure that all instrumentation, alarm settings, microprocessor signals and hardwire trips pertaining to the installation are functional. This will also check that signals from the field instrumentation are displayed locally and are being correctly relayed to the computer interface rack, as well as to the computer system. Flushing and Cleaning of Lines and Vessels with Water; The purpose of this activity is to clean all items of pipework and the vessels that make up the installation.

This task shall also ensure that there are no obstructions, blockages or any potential contaminants in any of the process lines or vessels that may have resulted from materials being left inside the system from the construction phase. If chemicals incompatible with water are to be used, it is important that the pipelines and equipment are thoroughly dried prior to introduction of the chemicals. This is normally done by passing dry air through the plant. Assessment of Ancillary Equipment; The main aim of this assessment is to verify the performance of all ancillary equipment.

This may include pumps, fans, heat exchangers, condensers etc. Calibration of Vessels and Instrumentation; The purpose of this activity is to check the calibration and performance of all vessels and instrumentation pertaining to the installation. To a certain extent this will be carried out in conjunction with the system pre-checks to ensure that the correct set points and alarm points have been established for use in the water trials.

Start Up Protocol; The purpose of this procedure is to provide guidance for bringing the installation online starting from an empty non-operational system. Shut Down Protocol; The purpose of this procedure is to provide guidance for taking the installation offline starting from a fully operational system. Handover Each section should be read in detail to gain understanding about the particular requirements of the activity prior to undertaking the activity itself and completing the associated check list. For some specific plant items, start-up is know to present particular additional hazards; some examples of these are: Dryers — when starting up a drying system after maintenance or a plant shutdown, the actual temperature the dryer might reach before settling out with the control system may result in an increased chance of a dust explosion; Furnaces — explosions may occur if ignition of fuel is delayed; Vessels, Tanks, Reactors — ignition of flammable vapours introduced may occur for systems relying on elimination of oxygen to prevent explosions, unless inert gas purging is carried out effectively; Reactors — start-up of batch reactors after agitator failure may cause an uncontrollable exothermic reaction.

Human factors The appropriate design of a procedure is critical in the reduction of human error within process operations. Generally there are four types of procedure: Procedures that provide general operating guidance; Procedures that provide an aid to meeting operating aims; Procedures that are mandatory and prescribe behaviour; and Procedures that are used as a training tool. Task analysis The content of important procedures should be based on some form of formal task analysis method to ensure that the procedure accurately describes the task it refers to.

The following issues should be considered in assessing operating procedure documentation: There should be no easier, more dangerous alternatives than following the procedure. There should be a suitable QA system in place to ensure that the procedures can be kept up to date and that any errors are quickly detected and hence corrected. The procedures should not be needlessly prescriptive. The best way of ensuring that procedures do not become overly prescriptive is through involving the operator during the design stage. Procedures should contain information on the requirements for the wearing of personal protective equipment during the task.

Any risks to the operator should be documented at the start of the procedure, based on a risk assessment of the task. An appropriate method of coding each procedure should be used.